As an important factor determining the performance of thermal imaging infrared materials greatly affect the development of infrared technology. High-performance infrared materials can better speed up the development and application of thermal imaging lenses in various fields. The common materials mainly include chalcogenide glass, germanium, ZnS, ZnSe, Si etc. chalcogenide glass has attracted the most attention and recognition in the industry due to its unique comprehensive advantages among them.

Chalcogenide glass is composed of two or multi elements including S, Se, Te in the VI main group of the periodic table and supplemented by other elements. The transmission range covers three atmospheric windows including 1-3μm, 3-5μm and 8-12μm. In the long-term practical application of thermal imaging systems, the chalcogenide glass shows a big advantage comparing other materials.

Optical athermalized is the most popular design for applications with a wide temperature range such as security, automotive etc. Chalcogenide glass is regarded as the preferred material for this design due to its advantages of lowest thermo-optical coefficients and multiple types, which can not only match a lot of reasonable optical structures, but also achieve better optical athermalization performance.

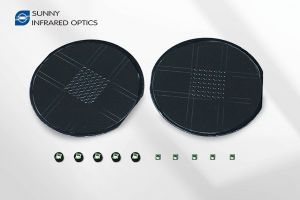

Chalcogenide glass is an amorphous material with a low softening temperature. In that case, it is not only suitable for polishing and diamond turning, but also for molding which can meet all kinds of mass production needs. It brings high efficiency and cost advantages.

As a traditional infrared material, Germanium is a scarce material due to its limited reserve and high mining cost. Chalcogenide glass gets popular in the market and has gradually replaced germanium in some applications, since it is rich in raw materials for stable supply.

Although chalcogenide glass has the irreplaceable advantages of other infrared materials, it puts forward higher requirements for processing and coating since its mechanical strength is not so good and thermal expansion coefficient is large. So it has relatively high industry technical barriers.

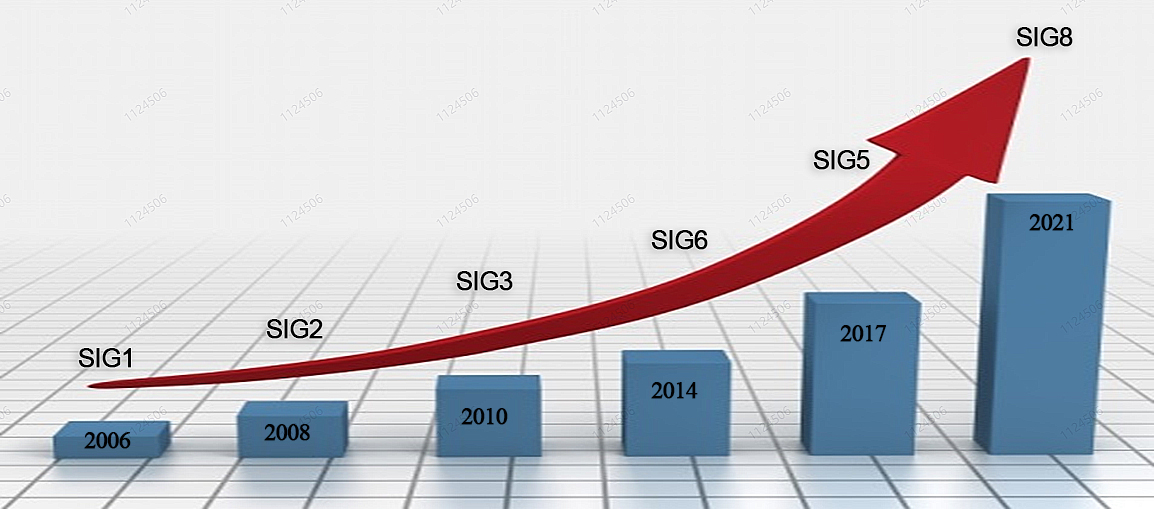

As the first company which provides one-stop production service from raw material to lens assembly in the world, SUNNY INFRARED OPTICS has strong capacities of R&D, manufacturing and processing for chalcogenide glass. Since its establishment in 2006, our company has successfully developed 6 types of chalcogenide glass and put into application. We will continue to work with industry partners to jointly lead the development of chalcogenide glass technology and promote industry upgrade. If you have various needs for solutions to infrared thermal imaging lens, please feel free to contact us.

+86 574 6253 0985

No. 360, 362 Fengyue Road, Yangming Street, Yuyao, Zhejiang Province, China

Copyright © Ningbo Sunny Infrared Technologies Co., Ltd. (Subsidiary of Sunny Group) | Sitemap | Technical Support: