With the widespread application of infrared thermal imaging lenses in the civilian field, the infrared coating has attracted much industry attention and research since it determines the imaging performance and the lifespan of lens. The specific functions of the infrared coating are related to the application of infrared thermal imaging systems. Due to the high refractive index, poor physical and chemical properties of the substrate material, the interference will cause serious energy loss and the surface will be easily damaged by environmental factors without the protection of coatings. Therefore, one or more layers of infrared coating are usually applied to the surface of the substrate, which can not only significantly improve the energy within the waveband, reduce stray light, but also improve the physical, chemical, mechanical, and electrical properties of the lens.

The selection of external surface coating is most commonly categorized as HE (High Efficient), HD (High Durability), DLC (Diamond-Like Carbon), and SDLC (Super Diamond-Like Carbon) depend upon the application of infrared thermal imaging lens. Due to the common and specific difference between the coatings, it can be difficult to choose the most suitable one without understanding the characteristics of each type. Therefore, this article will focus on introducing the selection of external surface coatings for lenses under the current mainstream applications.

Security Application:

Security application such as seaports, forests, and firefighting generally have complex environments. So the external surface coating must meet strict environmental adaptability requirements, especially the resistance to wind and sand, water vapor, and salt spray. Therefore DLC and SDLC coatings are generally applied. If the thermal camera is equipped with DLC window, the HE coating with higher transmittance could be applied.

Scenarios such as airports, schools, and hospitals usually have lower environmental durability, and HE or HD coatings can be applied based on the priority of transmittance requirements.

Industrial Thermography:

Most of devices for industrial thermography are handheld with moderate abrasion. So the external surface of the lens will be coated with an HE coating for high accuracy in mild environments. And HD coating is usually applied for complex environment, which could offer better reliability.

Automotive Night Vision:

The thermal camera is mounted on the front grille position and exposed to complex environments, such as strong light, sand dust, mud water, fog and haze. So it is generally equipped with a protective window to meet durability tests such as high temperature and humidity, vibration, rain-wiping, and impact. HE Coating can be applied to the external surface of the lens.

Outdoor Sports:

For aiming and observing outdoor scenes with no special requirements, the coating can be applied based on its reliability, transmittance, or aesthetic indicators. So SDLC and DLC coatings are highly favored by end users with their black and translucent appearance.

There is some significant differences between the coatings produced by each manufacturers due to processing technology. And it is difficult to achieve the best performance in all aspects because of the technical and cost limitations. So it is necessary to consider the lens aperture, cost requirements, and other factors to confirm the usage scenario and durability when facing the selection of coatings.

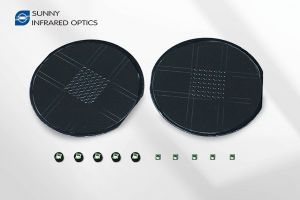

Sunny Infrared Optics has been involved in the field of infrared coatings since 2006. We have rich experience in understanding and developing various types of infrared applications, including visible light, NIR, MWIR, and LWIR coatings. Sunny is always at the forefront of technological innovation, production stability, and reliability. We will continue to focus on innovative exploration of "new functions, new processes" to help thermal imaging technology achieve wider applications.

+86 574 6253 0985

No. 360, 362 Fengyue Road, Yangming Street, Yuyao, Zhejiang Province, China

Copyright © Ningbo Sunny Infrared Technologies Co., Ltd. (Subsidiary of Sunny Group) | Sitemap | Technical Support: